RECOIL OFFGRID Preparation Infographic: Strength vs. Toughness

If you've ever broken a cheap knife or tool, you know that material choice is a major element of durability. That $30 knife from the clearance rack at your local outdoor store might be pretty decent, or it might bend, chip, and dull after a few uses — the type of steel used and how it's heat-treated make a huge difference. Either way, it's likely that the packaging attests to how strong and tough the blade is. If you have no frame of reference about the materials used, it's hard to know what those terms mean, or if they're just pointless marketing hype.

Unfortunately, our interchangeable use of these two terms just makes things more confusing (much like accuracy vs. precision). From a materials engineering standpoint, strength and toughness are two very different things, and this isn't just important for pedantic language nerds. Understanding these differences can help you get a better idea of what you're looking for in a piece of survival gear, describe it appropriately, and narrow down the specific type of material you need (e.g. strong tungsten carbide or tough 1095 high carbon steel).

In a nutshell, toughness is resistance to breaking force — the ability to bend and deform rather than crack. Strength is resistance to deformation — the ability to maintain its shape under load. (Strength also has several sub-categories, such as impact, tensile, and compressive, but that's a topic for another day.)

The tires on your car are tough but not strong; a dinner plate is strong but not tough. In this way, the idiom “tough as nails” is surprisingly accurate, since we've all seen a wayward nail bend into a pretzel rather than snap in half. The following infographic from PolymerSolutions.com shows a comparison between toughness, strength, and hardness (a subject we've addressed in a previous article). In knife steels, increased strength generally correlates with increased hardness.

This understanding of strength and toughness can also be applied to other materials. Composites such as carbon fiber and fiber-reinforced nylon are both strong and tough, favoring toughness and flexibility over pure strength. Ceramics are extremely strong, but not very tough. Most stainless (high-alloy) steel is reasonably tough and strong, but there's a lot of variation depending on the specific stainless composition — see the knife steel comparison guide for more details.

The following charts from the University of Cambridge offer a helpful comparison between strength and toughness for various materials. Additional charts are available for more detail on specific material sub-categories — you can view all the charts here.

From a practical standpoint, you can see that adding nickel to steel can make it tougher, and adding carbon can make it stronger. Toughness is ideal for chopping tools like a machete, whereas strength is preferable for a slicing blade. Once you know this, you can look up the properties of the steel used on that clearance-rack knife we mentioned, and determine if it'll meet your needs. Check out this comprehensive steel chart from Knife Informer for a deeper understanding of how other elements can alter a knife's toughness and strength.

So, next time you hear a product called “tough as nails,” remember that you could just as easily call it “tough as gold.”

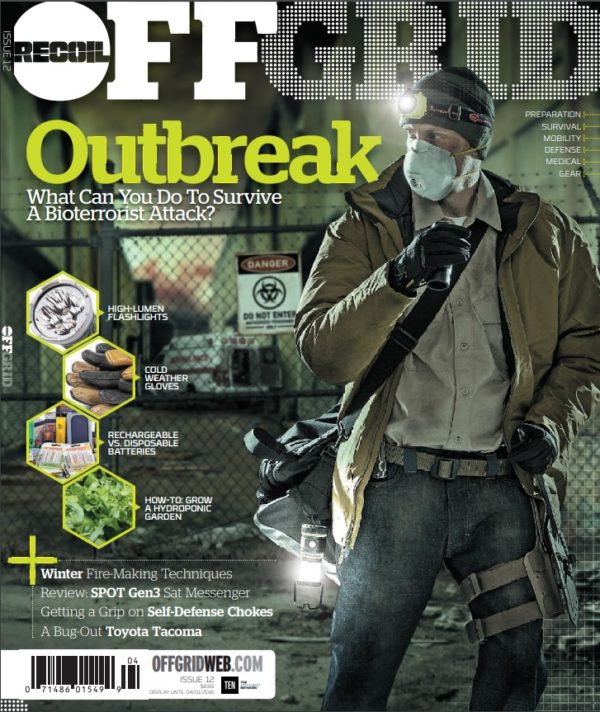

STAY SAFE: Download a Free copy of the OFFGRID Outbreak Issue

STAY SAFE: Download a Free copy of the OFFGRID Outbreak Issue

No Comments