RECOIL OFFGRID Survival Primitive Technology: Wood Ash Cement

Cement is a substance that surrounds us every day in the city and suburbs, and along with asphalt, it forms the basis for most of our urban developments. But have you ever considered how it's made? No, we're not talking about driving to the local hardware store, buying a bag, and adding water. If you needed to make your own cement from scratch, how would you do it?

In his latest video, the Aussie survival instructor at Primitive Technology shows how to make improvised cement from natural wood ash. He begins by burning dry bark in a clay kiln design he demonstrated in a previous video — you can watch that here. Once the bark was fully combusted and the fire died out, a pile of dry ash was left at the base of the kiln.

He then carefully mixed this with water, pouring off the excess until desired moisture was achieved. A ball formed from this paste was heated in a fire then dropped into water, and crushed clay was incorporated to reinforce the ash. After setting for three days, a cube made from the wood ash cement proved hard and moisture-resistant.

Although materials such as wattle and daub and adobe may be able to produce viable long-term structures, this wood ash cement is substantially more advanced. Modern cement's weather-resistance is outstanding, and this improvised variety appears to share this characteristic. Check out the video below to see the entire cement-making process:

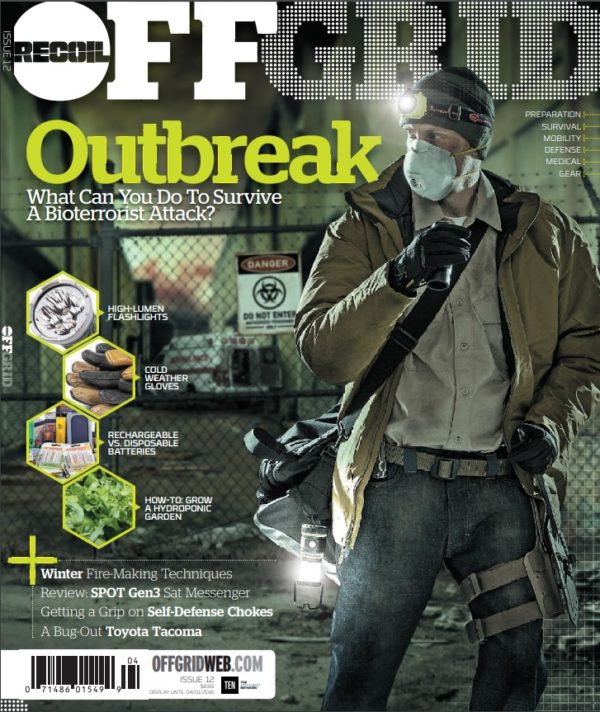

STAY SAFE: Download a Free copy of the OFFGRID Outbreak Issue

STAY SAFE: Download a Free copy of the OFFGRID Outbreak Issue

No Comments