RECOIL OFFGRID Gear Gunfighter Design: Hard Use Tools for Serious People

In This Article

Rob Ziarnick, founder and owner of Gunfighter Design, has been designing and making blades for over five years and decided it was time to test the limits of his product. He reached out and asked if I could take a beautifully crafted, handmade knife and, “put it through an insane amount of abuse and write about it”. When Rob offered to send me a sample of his POPS (Professional Outdoorsman Precision Skinner) MK2 and submit it to some gnarly testing, how could I refuse?

Gunfighter Design has an interesting story that started back in 2018. With the goal of making a great knife, the original design was a living room collaboration with Rob's friend and colleague Michael Baccellierli (aka Buck). Both Buck and Rob spent time addressing the shortcomings they encountered with knives in the past. Both were Marines and Snipers who broke knives while on combat deployments. Strength, ergonomics, functionality, and usefulness in more than one task lead to their prototype design, the Ravens Head. The double thumb relief or DTR was born, as well as the idea to incorporate a glass breaker. After making the first Ravens Head in a small propane forge with a piece of 80CrV2, it sent Rob on a journey of making knives as a business. Just as he was getting started, he was struck by a drunk driver, and was unsure if he could ever bladesmith again. But Rob is as tough as the knives he makes, and was back in the bladesmithing saddle in no time. Partnering with Eric Moser, a retired Green Beret Sniper, machinist, and someone who also had experience with knives breaking in combat, they began production with a new and improved design.

Videos of all kinds of blade destruction tests exist, but I didn’t want to wreck a perfectly good knife just for the sake of seeing it broken. At least not at first. I decided that I wanted to push its limits in a functional sense, before seeing what it might actually take to physically damage it beyond repair. Most knives are typically capable of performing three basic functions, piercing, chopping and slicing. The POPS MK2 was going to be evaluated on its ability to retain its edge and original design specs, while performing those functions during testing.

POPS MK2 is an absolute beast of a blade, not because it's the longest fixed blade out there, but because of its design and composition. Made from CPM 3V, it's forged from powdered, high carbon steel with a high amount of vanadium. Crucible Particle Metallurgy, designated by the CPM has a much finer grain pattern, and a more even dispersion of alloy elements. 3V indicates that the steel has around 3 percent vanadium, which is specifically used to increase hardness and edge retention. CPM 3V is specialized steel that is normally used in industrial shear blades, or commercial forging punches, but Gunfighter Design is using it in the form of a skinning knife!

Above: Several materials were selected to test the blades hardness, sharpness and durability. These include seasoned maple batons, a brass rod, and a copper tube.

The blade itself is 3.5 inches, and 8 inches over all, with a girthy width of 5mm. A functional glass breaker is ground into the end of the butt, and titanium eyelets hold G10 handle slabs in place. For a fixed blade on the short end of the spectrum, it has enough mass to let weight and gravity do most of the cutting work. It's a thick, wide blade, and the bevel skirts the border between meat cleaver and hatchet. One of the most unique features is its Double Thumb Relief on the spine of the blade. Placing your thumb on the spine when holding a knife is sometimes called the “saber grip”, and it is used to extend your reach. Adding a relief notch affords more control, and the second relief notch lets you work the blade with more dexterity in tight places.

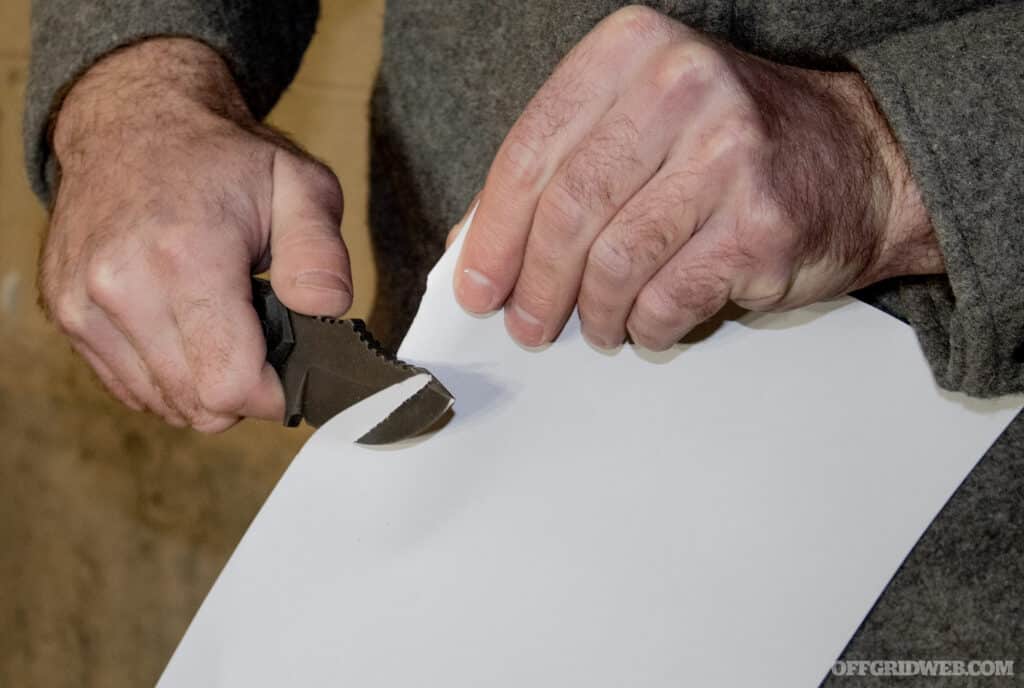

Before getting into the serious performance tests, I wanted to establish a relatively simple baseline of its cutting capabilities. One of the best ways to do this is simply letting the edge slice through a piece of standard printer paper. The edge of the POPS does this easily enough, although the width of the blade slows down its momentum. This is perfectly fine as the blade is made for breaking bone and cutting through ligaments and sinew. Since it’s a brand new knife, there are no chips or rolls along the edge. Now that I know that it's sharp and will slice easily, it's time to test its piercing and chopping performance.

Above: Being able to smoothly slice a piece of printer paper is an easy way to test a blades' sharpness.

For chopping, I have three items of varying densities: wood, copper and brass. First up is a seasoned hard maple baton. Summoning my inner Jay Nielson, I swing the POPS into the wood with as much force as I can muster. The blade chews through the baton like a hungry beaver, leaving the edge perfectly intact. To add extra force behind it, I use a second baton and hit the spine of the blade to drive the edge into the wood deeper. To remove it from the wood, I pry the blade as far as I can back and forth. The steel remains straight, and the edge remains true. Turning it on its point, I baton the blade tip-first into the wood as far as I can go, prying it back and forth to remove it. POPS stares back at me unphased.

Above: Seasoned sugar maple is a hardwood that will give an axe a run for its money, but its just a walk in the park for the POPS MK2.

Okay, great, it can handle wood, nothing supernatural about that, so lets try it against some soft metals. POPS is batoned into copper pipe, and then into a brass rod. The copper pipe is cut and bent, and the brass rod is cut through as well. Still the edge of the POPS remains in pristine condition. No rolls, no chipping. Maybe some of the anodized finish is blemished, but beyond that, it's like nothing ever happened. I do a follow up slice test on the paper and notice a slight decrease in sharpness. But after a few passes on an 800 and 1000 grit stone, and a little stroping, it's slicing better than ever.

Above: Copper has a hardness between 45 and 50 on the Rockwell Hardness Scale (HRC).

At this point, I feel the POPS MK2 has held up to more than would ever be asked of it, even in the most difficult settings. It can be pried without losing its straightness. If it can cut through brass, it can surely cut through bone unphased. Obviously the heat treatment–a knife making process that affects the quality of steel hardness–was done expertly. The edge sharpened easily, and over all, I would rank this as a top notch hunting knife. Unfortunately for the POPS, I was asked to punish the blade, and needed to crank things up a notch to push it to its limits.

Above: Brass, a composite of zinc and copper, has a hardness of around 30 HRC.

I want to preface this by stating, on the record, that I love handmade knives, and I cringe every time I see destruction testing taken to the extreme. Someone’s hard work, skill and time goes into every blade, and to purposefully destroy one seems disrespectful to me. So just know, that what I’m about to do may have been harder on me than it was on the knife.

On a knife, the tip is one of the weakest, if not the weakest point. Any inconsistencies in the heat treatment can cause the tip to bend or break. I already know the tip of the POPS can hold up to hardwood and soft metal, but what about chipping its way through ice? For this punishment, I’m not using your normal, clear, run-of-the-mill ice. Instead I chip my way through four inches of stamp sand and gravel that's been frozen solid and compacted by a county snow plow over the course of several months. After several minutes of continuous chipping, POPS survives! The tip did not break, bend or roll, and it did not lose much of its sharpness. In fact, I would go so far as to say a hole could be augered for ice fishing using this blade if you were in a pinch.

Above: Chipping through a concrete mixture of ice and gravel proved to be a boring challenge for the POPS MK2.

Punishment number two is a test of its overall integrity. So far I've been focusing mainly on the edge and its functionality, and overall it seems bullet proof. But what about the handle and the rest of its construction? To find out what this thing is made of, I place the knife flat on the gravel strewn ice pack, and jump in my truck. Each truck tire exerts roughly 1,400lbs of contact pressure with the ground, and because I'm moving, that pressure is rolling along the width of the blade at different points at different times. Any problems with the heat treatment or handle construction will cause a critical failure of the blades integrity. First I back over the POPS with the rear tire, then the front tire, then drive forward and get it with the front, then again with the rear tire. POPS has been driven over four times. Then I repeat this process four more times for good measure for a total of 20 times. At one point I became nervous about the blade going through the tread of my tires, but I risk it all for the sake of science!

Above: The POPS MK2 awaits being run over, repeatedly, by a full size pickup truck.

Getting out of my truck, I walk around to see what happened to my beloved tanky POPS, and… it survives! Not only did it survive, but it seems completely indestructible at this point. The spine of the blade is still straight, the G10 handle slabs haven’t come loose, and if there is any damage at all, it's only to the anodized finish. Even the G10 appears unscathed after cleaning it up a bit.

At this point I'm facing a bit of a conundrum. I was asked to brutalize this thing, and aside from throwing it in the fires of Mount Doom, or dragon's breath, I’m not exactly sure what else to do to test it. My mind wanders to taking the blade to the range and throwing some lead at it, but lead is much softer than brass, no matter how hard you toss it at something. In fact, given the velocity, mass, and acceleration of your common 9mm, you’d only be exerting about 1,600lbs of pressure on the blade. Granted, at much faster speeds, but still, that's only a few more pounds than truck tires. And we just did that twenty times in a row. I wander through my garage looking for inspiration, and find it in the form of a 10lb sledge hammer. Believe it or not, depending on how fast and hard the swing is, a steel sledge hammer can produce astronomical amounts of pressure. We’re talking in the double digit tons of pressure.

Picking up the sledge, and placing the POPS down reverently on the compacted ice, I put on some safety glasses, and say some final words to one stubbornly durable knife. Aiming for the flat of the blade, I swing the sledgehammer overhead as hard and fast as I can. Ice and gravel spray violently in all directions. Wiping clear the debris from my safety glasses to assess the damage, I find, to my astonishment… POPS survives! Just to be sure, I swing again. POPS survives! And again. POPS survives! It isn’t until the sixth swing of the sledge that POPS suffers a catastrophic failure.

Above: It took an insane amount of punishment to finally inflict enough damage to cause the blade to break.

Failure occurred at where the handle meets the ricasso of the blade, which is a common place for a break to happen. Near the break, there is a titanium eyelet, and my best guess is that there was just not enough steel in that location to absorb the ferocious impact of multiple sledgehammer blows. Other than the break, the G10 seems a little roughed up but nothing major considering what it just went through. The blade itself is unbent, and when pieced back together, makes a perfectly straight line.

Iron is a magical element in the hands of someone who knows how to manipulate it. Mix it with the right additives and it becomes an alloy steel that takes on otherworldly properties. In the case of the POPS MK2, it is a steel blade that could outlast humanity if taken care of properly. Barring industrial cutting tools, or temperatures that exceed 2,000 oF, Rob, Eric and Gunfighter Design has brought a knife to market that you could depend on with your life. Although the blade is now broken, it will be kept as a reminder of what dedication to quality and attention to detail can achieve.

STAY SAFE: Download a Free copy of the OFFGRID Outbreak Issue

STAY SAFE: Download a Free copy of the OFFGRID Outbreak Issue

No Comments